The Food Code and HACCP Principles at Retail

Hazard Analysis & Critical Control Points (HACCP) is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product. As such, HACCP is a common sense approach to assuring food safety from harvest to consumption. Preventing problems from occurring is the primary goal underlying any HACCP system.

The Code includes HACCP principles.

|

Roll over the tabs to view more information. |

|

This content requires JavaScript enabled.

|

|

A flow diagram that delineates the steps in the process from receipt to sale or service forms the foundation for applying the seven principles. The flow of food in a retail or food service establishment is the path that food follows from receiving through service or sale to the consumer. Most food items produced in a retail or food service establishment can be categorized into one of three preparation processes based on the number of times the food passes through the temperature danger zone between 41°F to 135°F. Below illustrates three general process flows.

|

Roll over each process flow category to view descriptions. |

|

This content requires JavaScript enabled.

|

|

Prerequisite Program Standards

There are basic sanitation requirements considered prerequisite to establishing a HACCP program, and is one of the first steps in developing a food safety management system. See Managing Food Safety: A Manual for the Voluntary Use of HACCP Principles for Operators of Food Service and Retail Establishments for more information. The purpose of developing prerequisite programs is to implement a strong foundation of procedures that address the basic operational and sanitation conditions within a food establishment. When such programs are in place, greater emphasis can be placed on the hazards associated with the food and its preparation.

Prerequisite programs include:

- Vendor certification programs

- Training programs

- Allergen management

- Buyer specifications

- Recipe/process instructions

- First-In-First-Out (FIFO) procedures

Such programs should be in place to control the contamination of food, control bacterial growth, and maintain equipment.

Hazard Analysis

In developing a food safety management system, it is important for a food establishment to identify food safety hazards that exist in the flow of food from receiving to serving or sale. Once food safety hazards have been identified, it is possible to determine and implement control measures in order to achieve active managerial control.

in order to achieve active managerial control.

|

Click below the question to view the answer. |

|

This content requires JavaScript enabled.

|

|

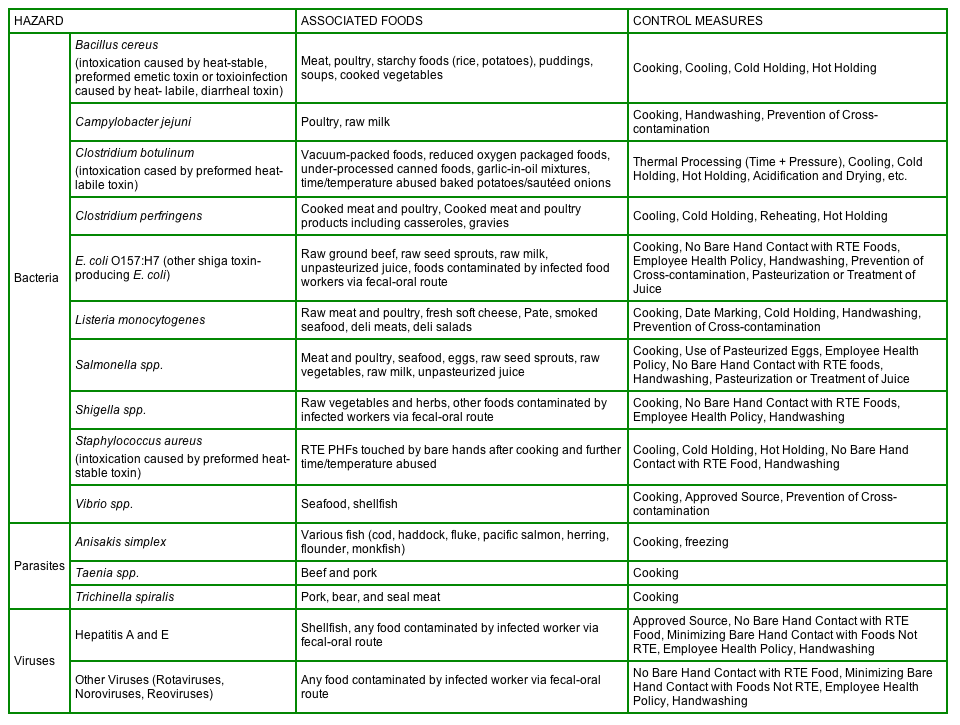

Below is a table taken from Annex 3 in Hazard Analysis, Managing Food Safety: A Regulator's Manual For Applying HACCP Principles to Risk-based Retail and Food Service Inspections and Evaluating Voluntary Food Safety Management Systems. Included are selected biological hazards found at retail, the associated foods, and control measures to address these hazards.

Critical Limits

The Code provides specific measurable criteria referred to as critical limits, which are designed to prevent, eliminate, or reduce hazards in foods. The critical limits are based on the best available science and pertain to control measures applied within operational steps. They are established in the cooking, cooling, and reheating requirements and are mainly found in Chapter 3 of the Code.

Variance and HACCP Plan

Specific food processes that require a variance have historically resulted in more foodborne illness than standard processes. They present a significant health risk if not conducted under strict operational procedures. These types of operations may require the person in charge and food employees to use specialized equipment and demonstrate specific competencies. The variance requirement is designed to ensure that the proposed method of operation is carried out safely. The Code provides some flexibility with regulatory approval for food establishments in terms of adhering to Code regulations via variances and HACCP plans. In some cases the Code requires a preapproved variance and HACCP plan and in others only the availability of a HACCP plan and adherence to it (see §3-502.11 vs. §3-502.12).

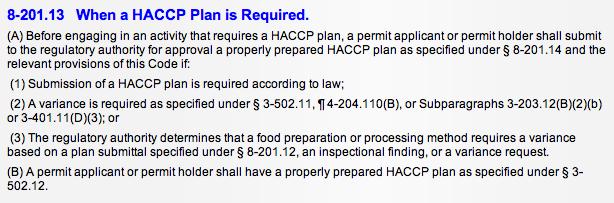

The image below is taken from §8-201.13 of the Code and specifies conditions under which a HACCP Plan is required.

According to §8-201.14, a food establishment that is required to have a HACCP plan must include the following in their plan and specifications:

- A categorization of the types of potentially hazardous foods in the menu such as soups and sauces, salads, and bulk, solid foods such as meat roasts;

- A flow diagram by specific food or category type that identifies critical control points and provides information on the following:

- Ingredients, materials, and equipment used in the preparation of that food, and

- Formulations or recipes that delineate methods and procedural control measures that address the food safety concerns involved;

- Food employee and supervisory training plan that addresses the food safety issues of concern;

- A statement of standard operating procedures for the plan under consideration including clearly identifying:

- Each critical control point,

- The critical limits for each critical control point,

- The method and frequency for monitoring and controlling each critical control point by the food employee designated by the person in charge,

- The method and frequency for the person in charge to verify that the food employee is following standard operating procedures and monitoring critical control points,

- Action to be taken by the person in charge if the critical limits for each critical control point are not met, and

- Records to be maintained by the person in charge to demonstrate that the HACCP plan is properly operated and managed; and

- Additional scientific data or other information, as required by the regulatory authority, supporting the determination that food safety is not compromised by the proposal.

Annexes

There are seven annexes located at the back of the document. While they were not adopted by 590 and are not part of the codified portion of the Code, they still remain a tremendous resource intended for regulator use but of interest to all.

The annexes are provided specifically to assist the regulatory authority apply the provisions uniformly and effectively. It is, therefore, important for users to preview the subject and essence of each of the annexes before using the document. Some of the annexes (e.g., References, Public Health Reasons) are structured to present the information by the specific Food Code item number to which they apply. Other annexes provide information and materials intended to be helpful to the user such as model forms that can be used, a delineation of the principles of HACCP, guidelines for establishment inspection, and criteria for certain food processes for use in evaluating proposed HACCP plans.

Annex 1 - Compliance and Enforcement

The purpose of this Annex is to set forth provisions, in codified form, that provide a full array of enforcement mechanisms while recognizing the diverse statutes and regulations that currently govern the operations of the thousands of state and local regulatory agencies.

Annex 2 - References

The Code makes frequent reference to federal statutes contained in the United States Code (USC) and the Code of Federal Regulations (CFR). Copies of the USC and CFR can be viewed and copied at government depository libraries or may be purchased as follows.

Annex 3 - Public Health Reasons / Administrative Guidelines

This annex can serve as a tremendous resource since it provides the public health rationale for the food safety provisions set forth in Chapters 2-7.

Annex 4 - Food Establishment Inspection

This annex provides regulatory agencies with guidance on planning, scheduling, conducting, and evaluating inspections. It also supports programs by providing recommendations for training and equipping the inspection staff, and attempts to enhance the effectiveness of inspections by stressing the importance of communication and information exchange during regulatory visits.

Annex 5 - HACCP Guidelines

This annex describes in details the seven principles of HACCP and how they can be utilized to develop an effective HACCP plan.

Annex 6 - Food Processing Criteria

The purpose of this Annex is to provide processing criteria for different types of food manufacturing/processing operations for use by those preparing and reviewing HACCP plans and proposals. Reduced Oxygen Packaging (ROP) and Smoking and Curing criteria are described in this annex.

Annex 7 - Model Forms, Guides, and Other Aids

The documents provided in this Annex are intended to facilitate adoption of the Code and the application of its provisions as they relate to applicants' and food employees' health and to food establishment inspections.